Image 1 of 11

Image 1 of 11

Image 2 of 11

Image 2 of 11

Image 3 of 11

Image 3 of 11

Image 4 of 11

Image 4 of 11

Image 5 of 11

Image 5 of 11

Image 6 of 11

Image 6 of 11

Image 7 of 11

Image 7 of 11

Image 8 of 11

Image 8 of 11

Image 9 of 11

Image 9 of 11

Image 10 of 11

Image 10 of 11

Image 11 of 11

Image 11 of 11

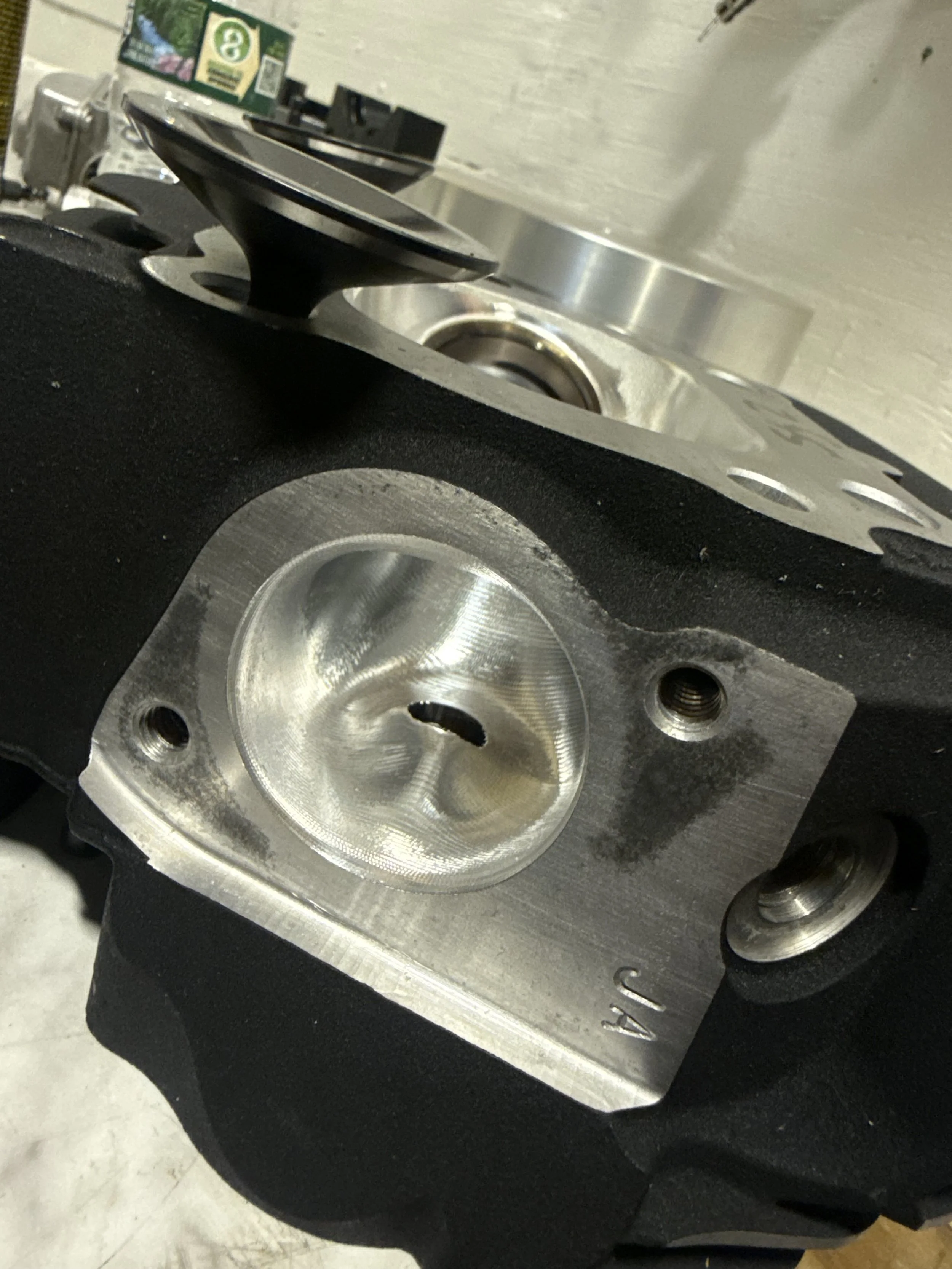

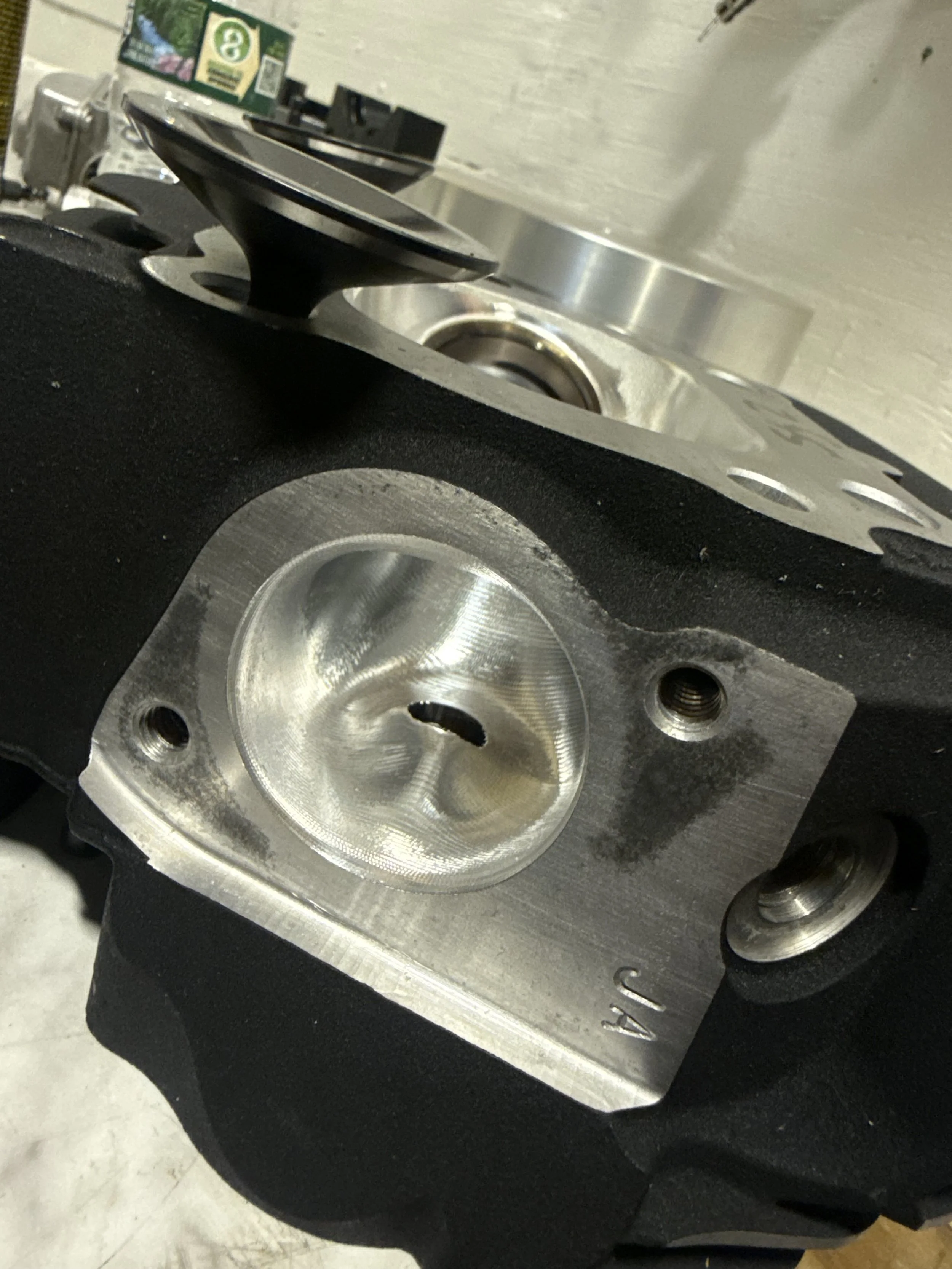

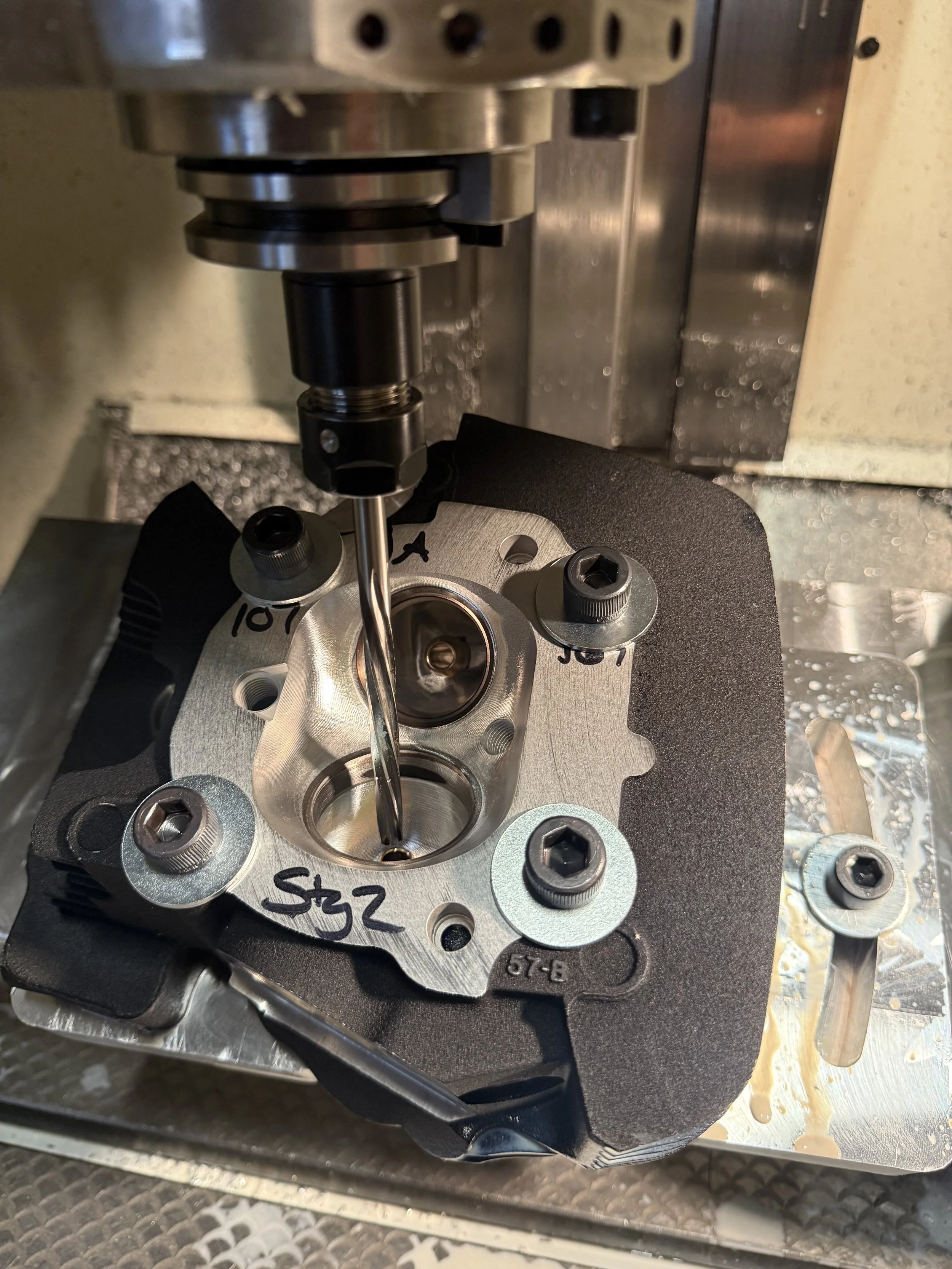

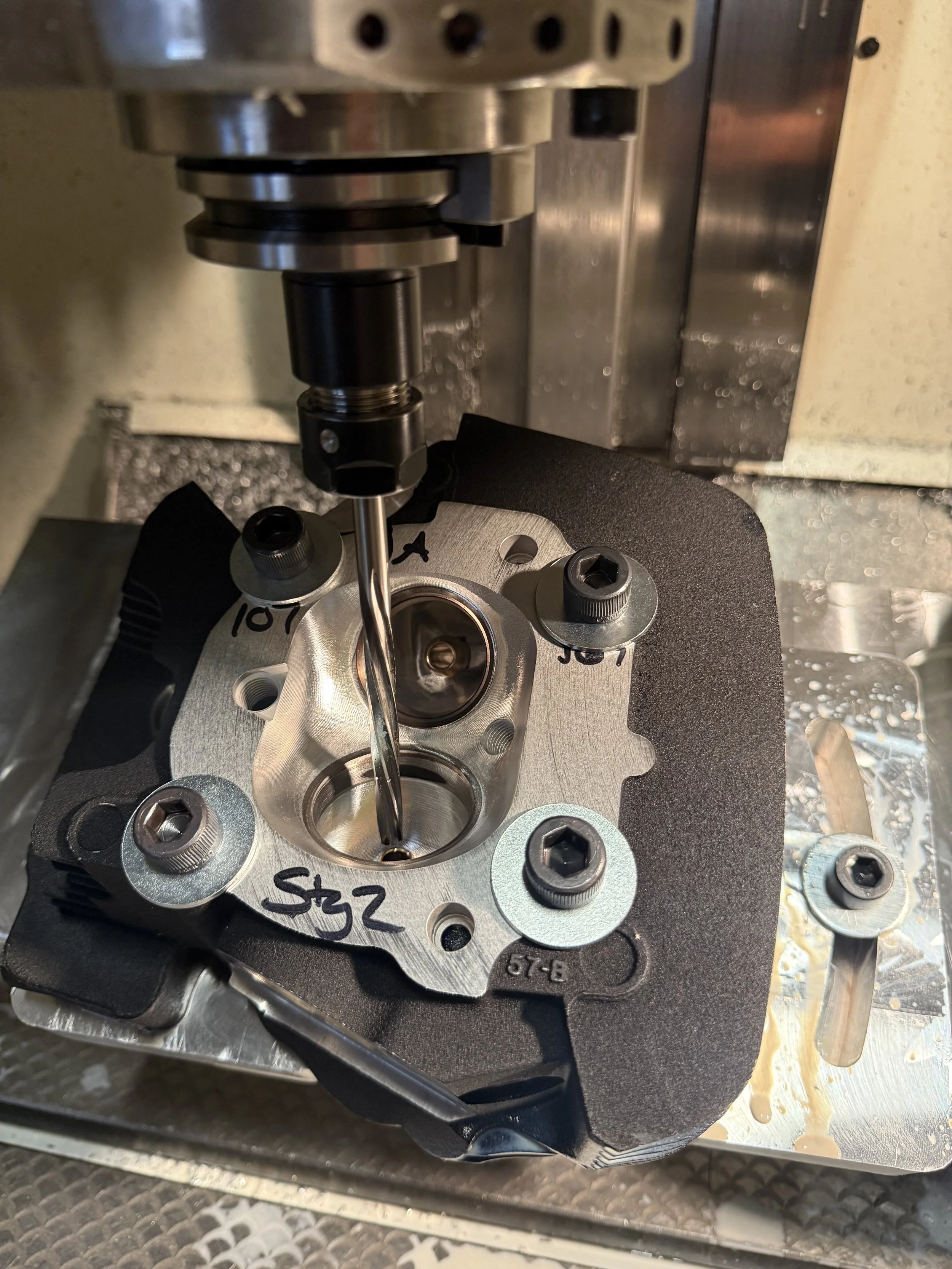

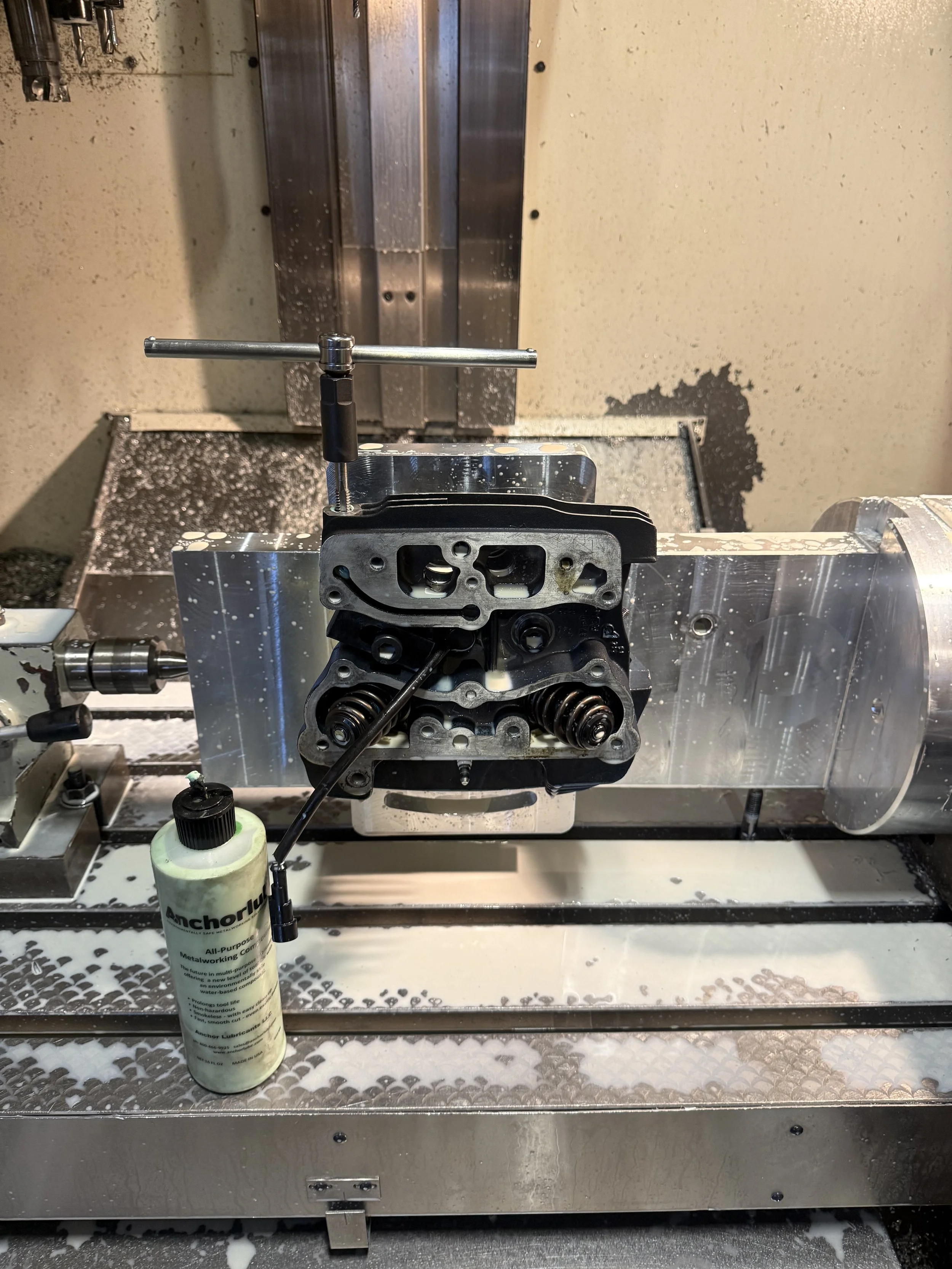

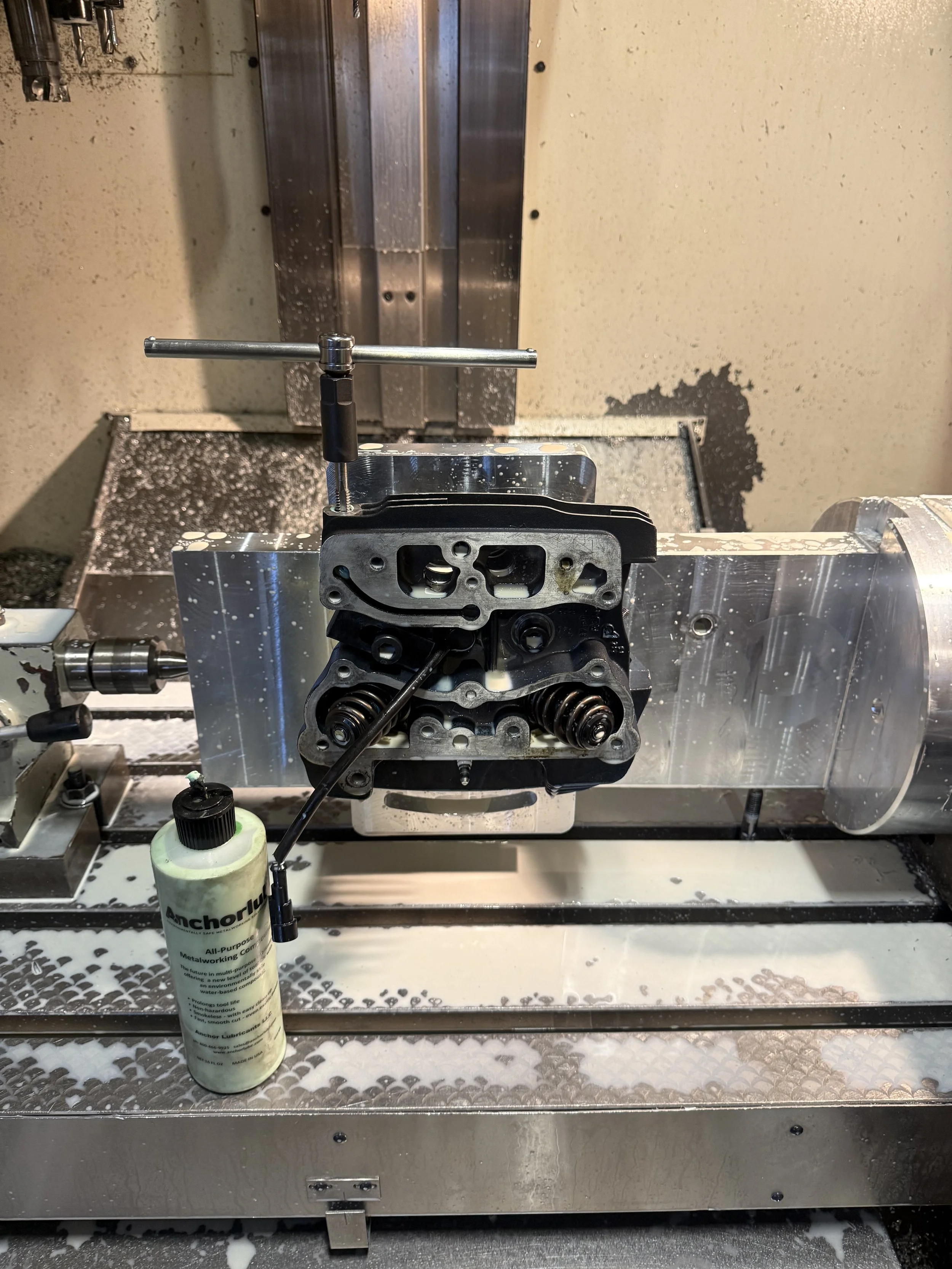

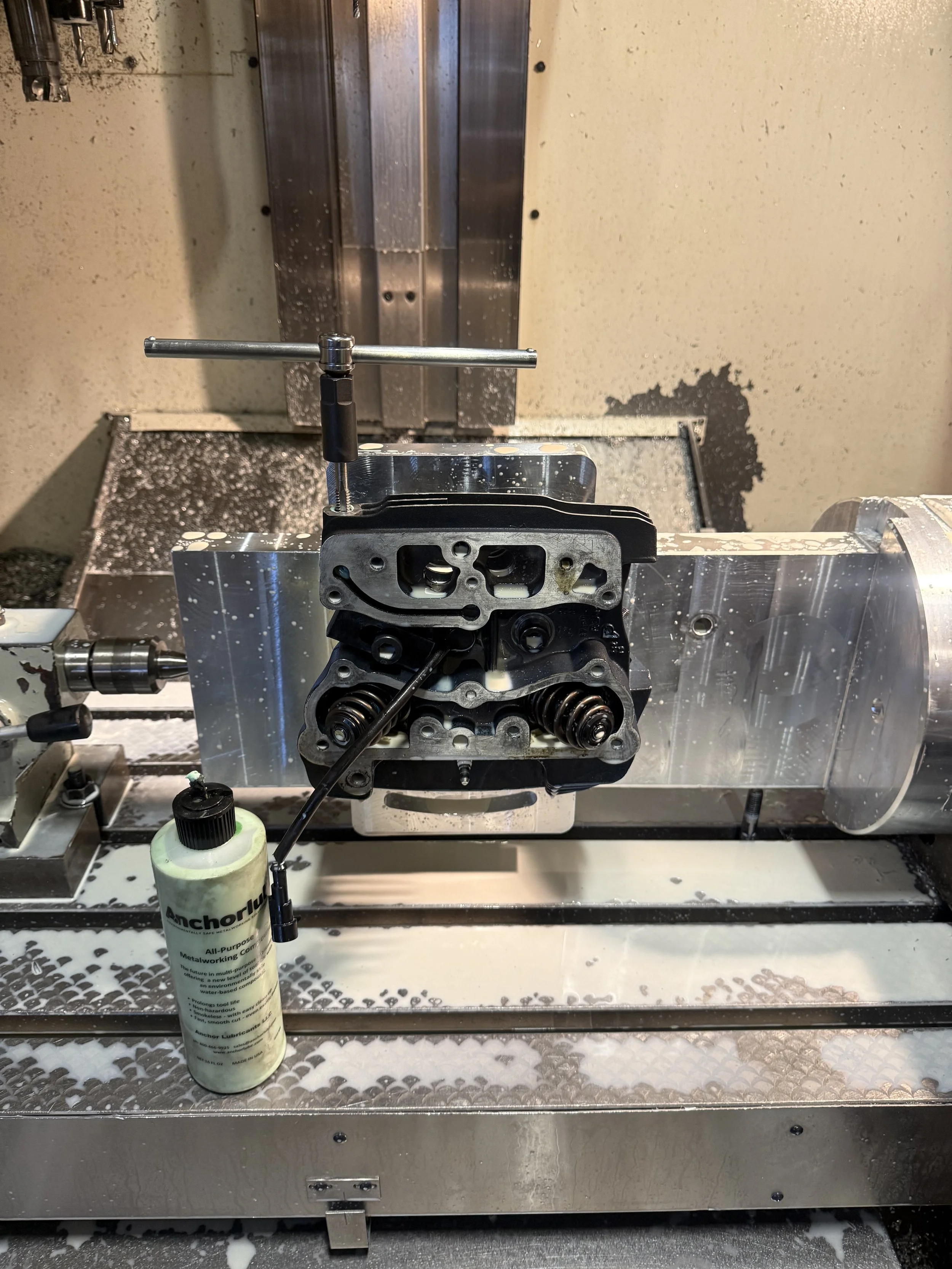

Twin Cam – Stage 4 Cnc Cylinder Heads

.Race-level CNC development using stock castings, designed to extract every ounce of power while maintaining durability and reliability:

Complete disassembly and full inspection of all components

Deep cleaning and media blasting of chambers and ports

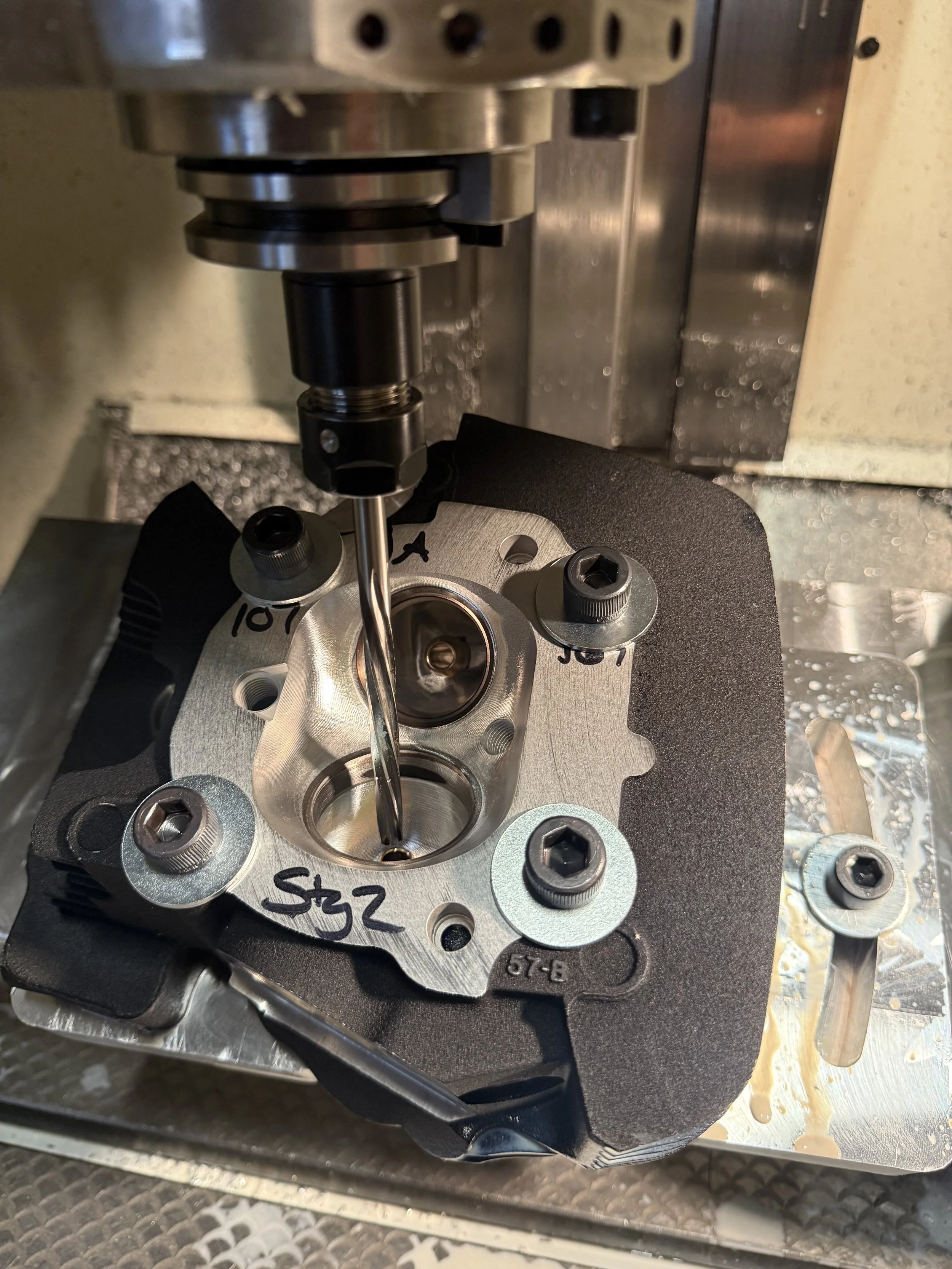

Full CNC porting of intake and exhaust runners, optimized for high-lift flow and velocity balance

Superior choice on 4.125”+ Bore engines

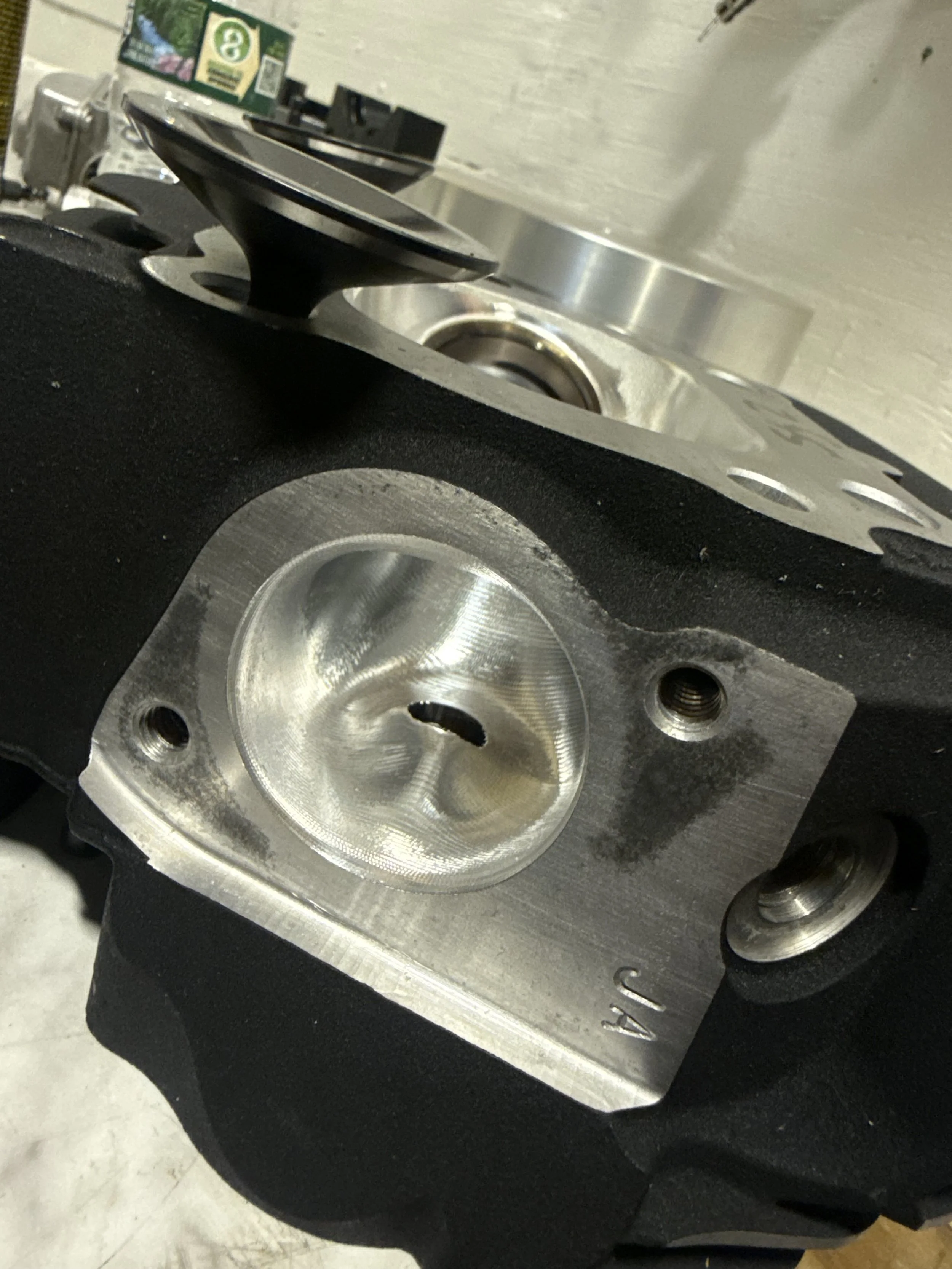

CNC-machined high-efficiency un shrouded combustion chambers tailored for max compression and quench control to accept CVO Dome pistons chambers are 98cc before decking

Precision 4-angle valve job on performance seats

2.000” stainless intake valves / 1.630” exhaust valves replace seats

Upgraded bronze taper valve guides for superior heat transfer and long-term stability

Premium high-tension beehive valve springs matched for aggressive cam profiles

CNC deck for exact compression control and perfect gasket sealing

Final ultrasonic wash and professional assembly

Result: maximum airflow and combustion efficiency from OEM castings — engineered for all-out race builds and high-compression performance engines.

Note: This is a send-in service for your existing cylinder-head cores.

Customer must ship in clean, rebuildable head cores for this service.

Pricing covers machining and labor only — no cores are supplied or exchanged.

Any additional parts or repairs required beyond the listed service will be quoted separately upon inspection.

.Race-level CNC development using stock castings, designed to extract every ounce of power while maintaining durability and reliability:

Complete disassembly and full inspection of all components

Deep cleaning and media blasting of chambers and ports

Full CNC porting of intake and exhaust runners, optimized for high-lift flow and velocity balance

Superior choice on 4.125”+ Bore engines

CNC-machined high-efficiency un shrouded combustion chambers tailored for max compression and quench control to accept CVO Dome pistons chambers are 98cc before decking

Precision 4-angle valve job on performance seats

2.000” stainless intake valves / 1.630” exhaust valves replace seats

Upgraded bronze taper valve guides for superior heat transfer and long-term stability

Premium high-tension beehive valve springs matched for aggressive cam profiles

CNC deck for exact compression control and perfect gasket sealing

Final ultrasonic wash and professional assembly

Result: maximum airflow and combustion efficiency from OEM castings — engineered for all-out race builds and high-compression performance engines.

Note: This is a send-in service for your existing cylinder-head cores.

Customer must ship in clean, rebuildable head cores for this service.

Pricing covers machining and labor only — no cores are supplied or exchanged.

Any additional parts or repairs required beyond the listed service will be quoted separately upon inspection.