Image 1 of 14

Image 1 of 14

Image 2 of 14

Image 2 of 14

Image 3 of 14

Image 3 of 14

Image 4 of 14

Image 4 of 14

Image 5 of 14

Image 5 of 14

Image 6 of 14

Image 6 of 14

Image 7 of 14

Image 7 of 14

Image 8 of 14

Image 8 of 14

Image 9 of 14

Image 9 of 14

Image 10 of 14

Image 10 of 14

Image 11 of 14

Image 11 of 14

Image 12 of 14

Image 12 of 14

Image 13 of 14

Image 13 of 14

Image 14 of 14

Image 14 of 14

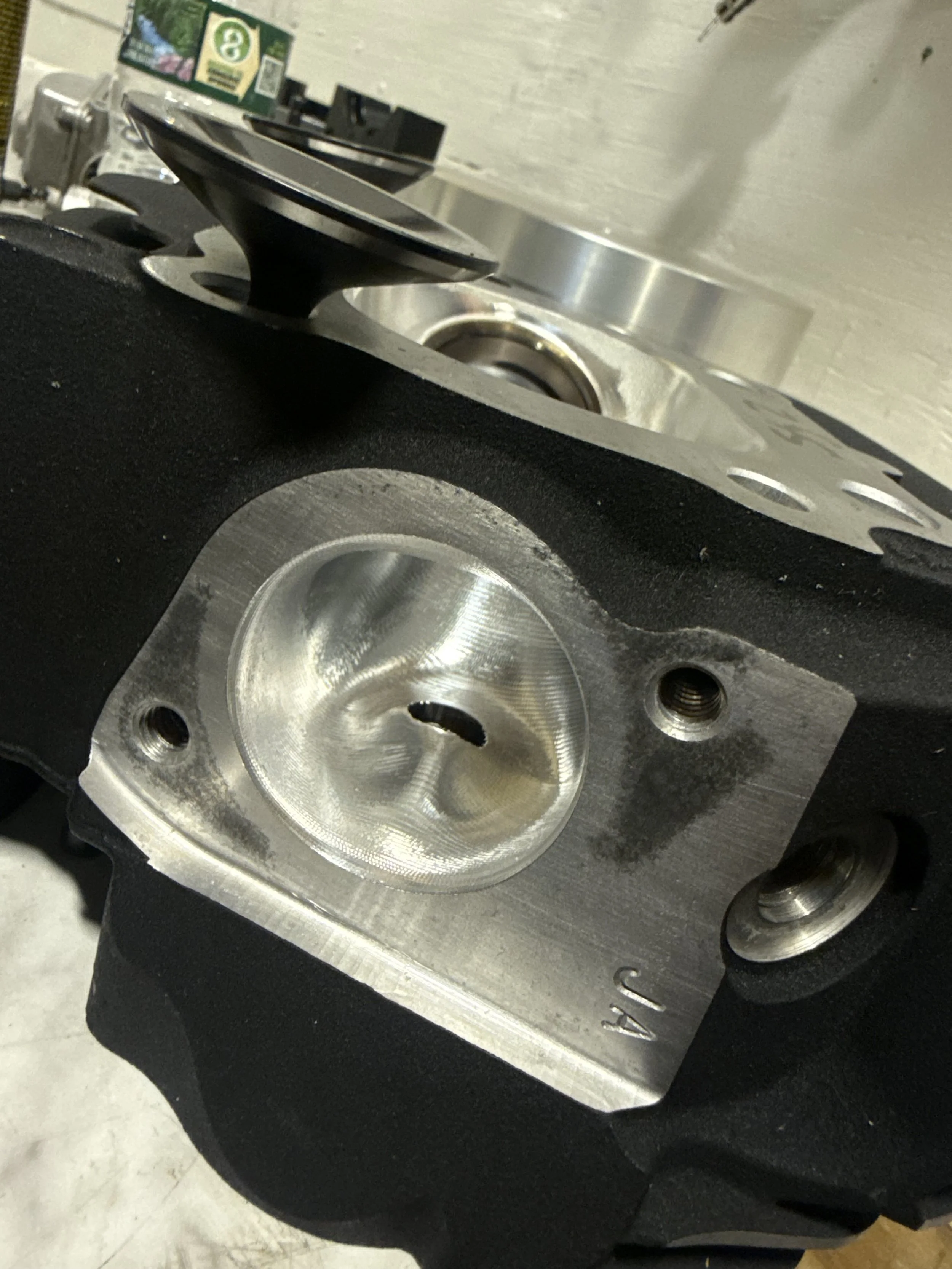

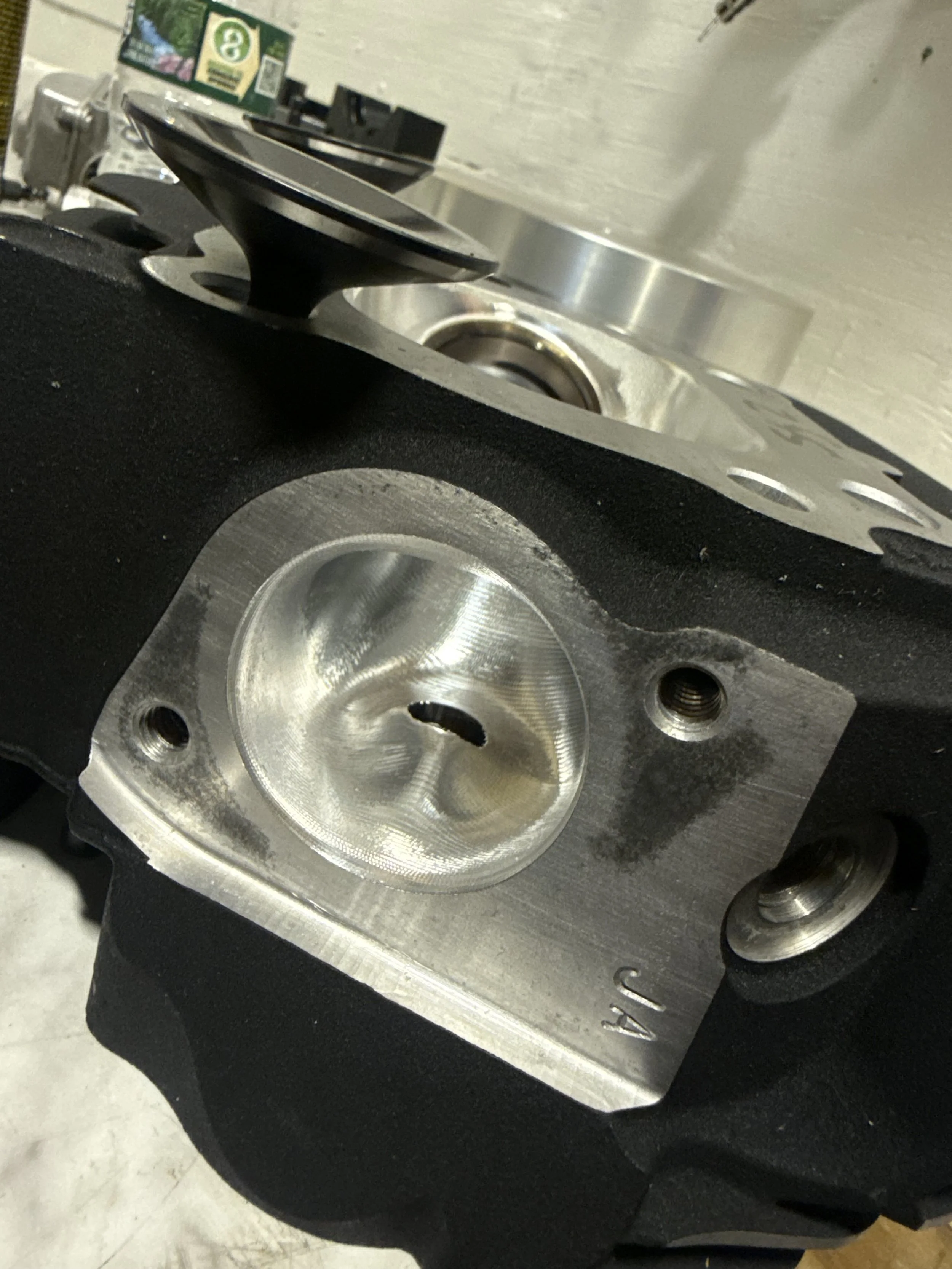

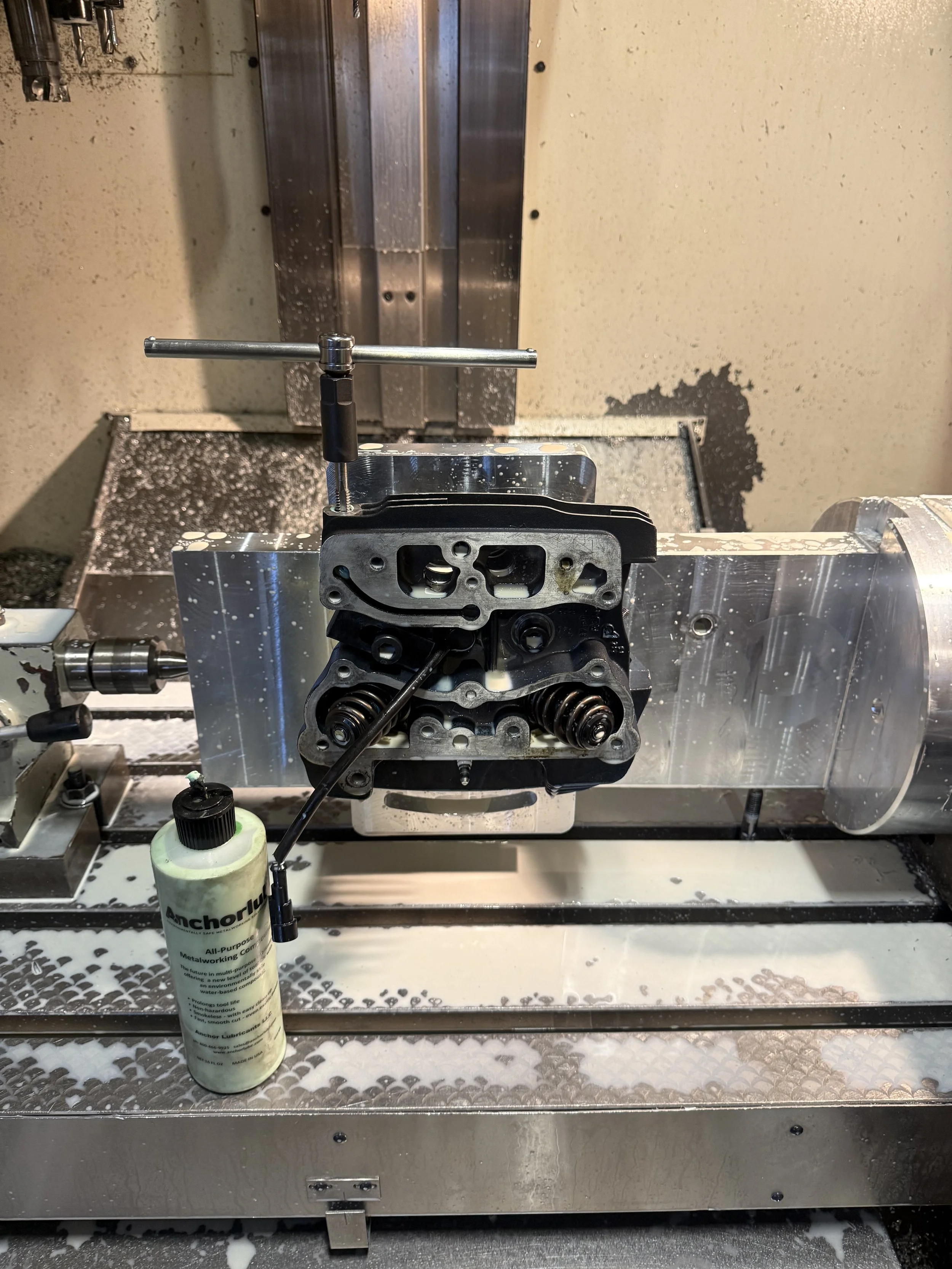

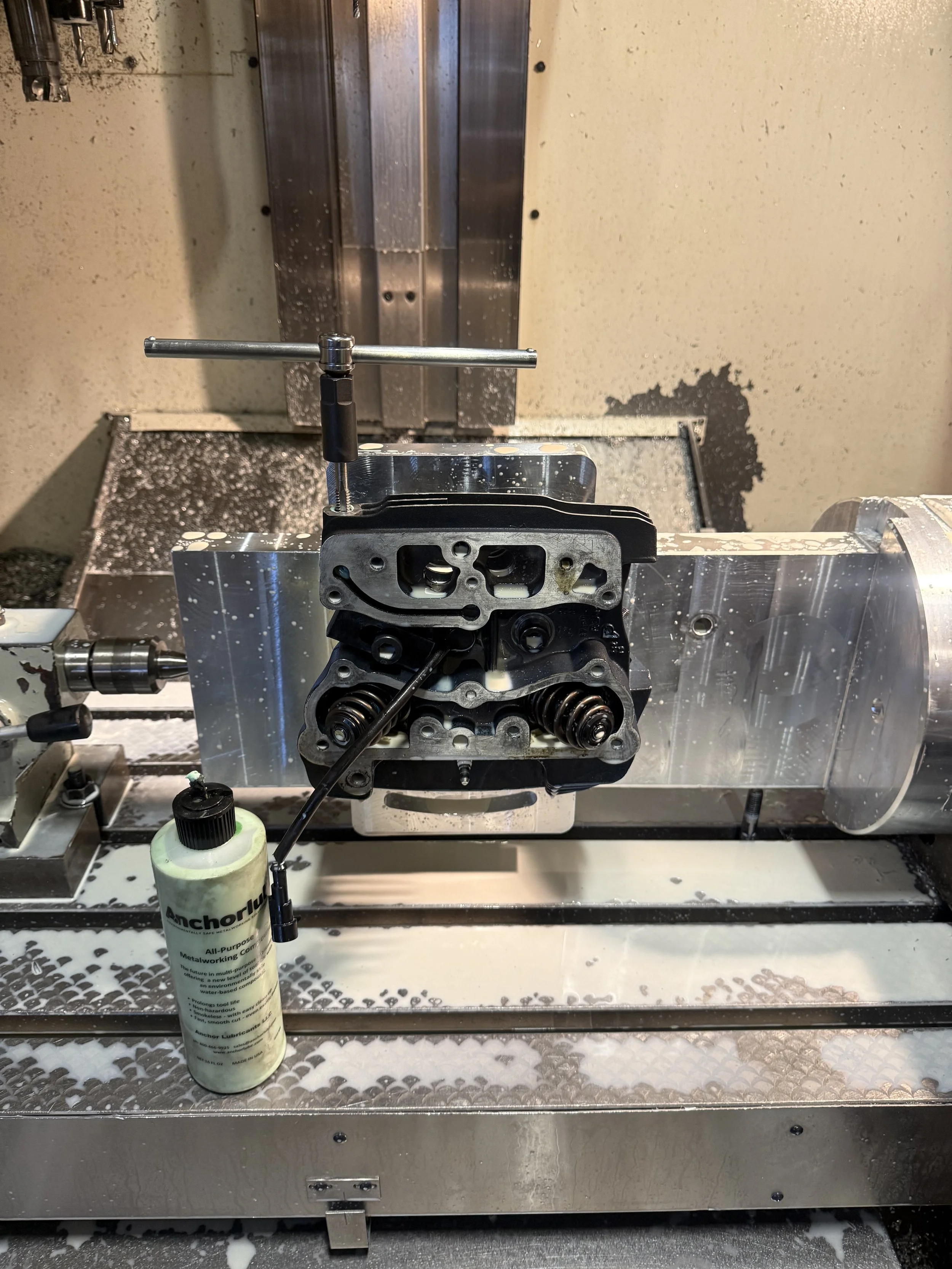

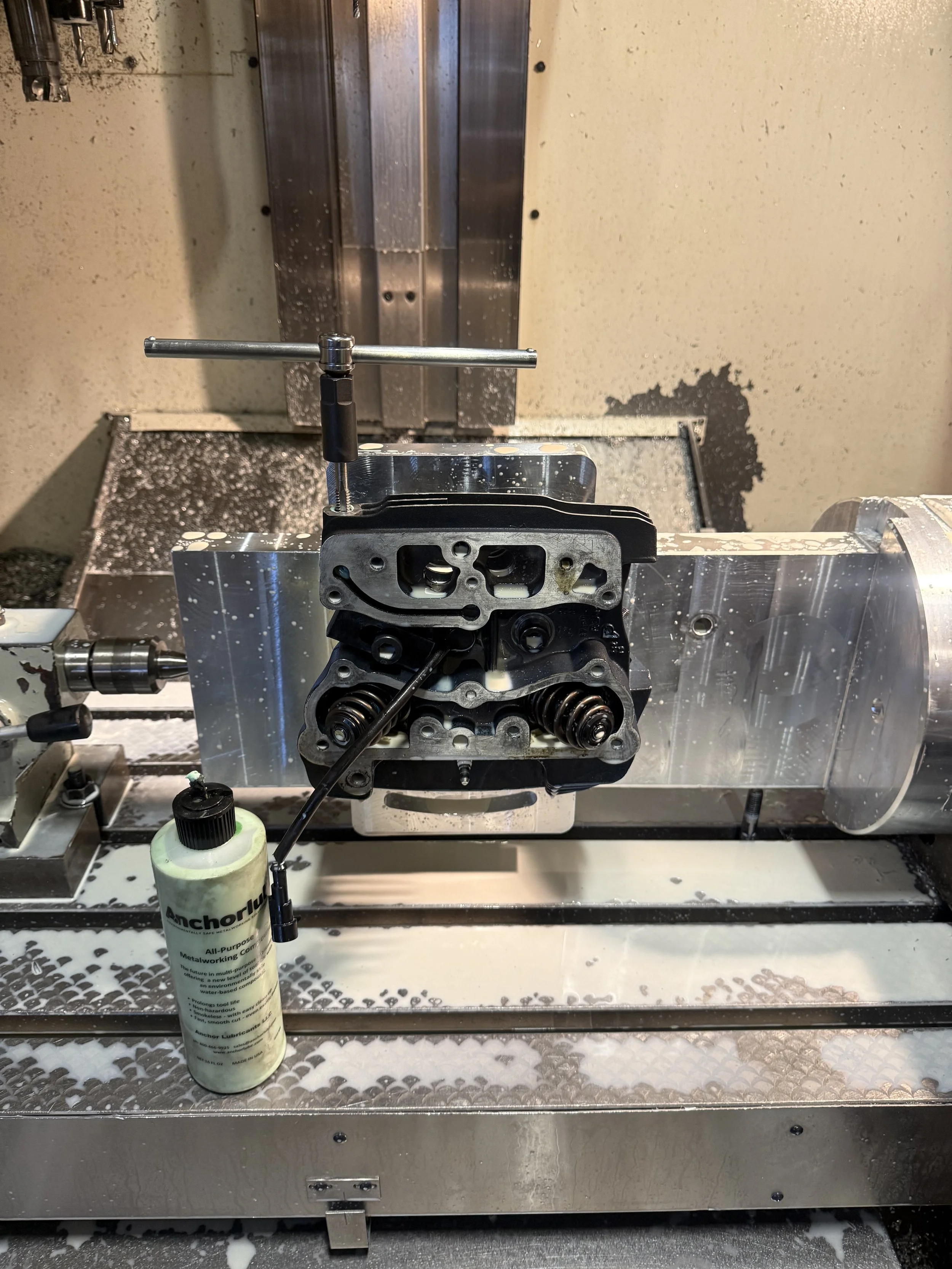

CVO Twin Cam – Stage 3 Cnc Cylinder Heads

.Race-level CNC development using stock castings, designed to extract every ounce of power while maintaining durability and reliability:

Complete disassembly and full inspection of all components

Deep cleaning and media blasting of chambers and ports

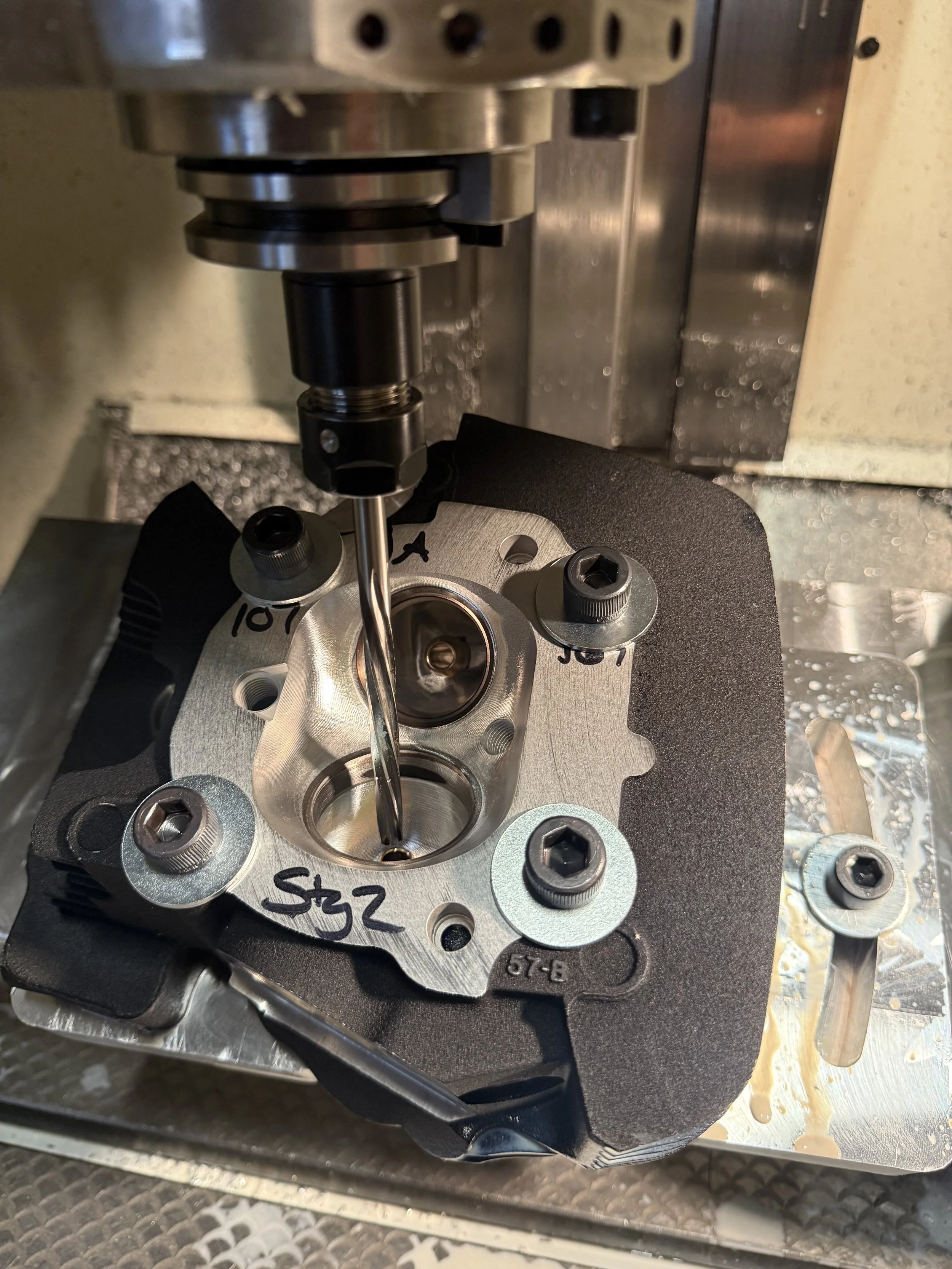

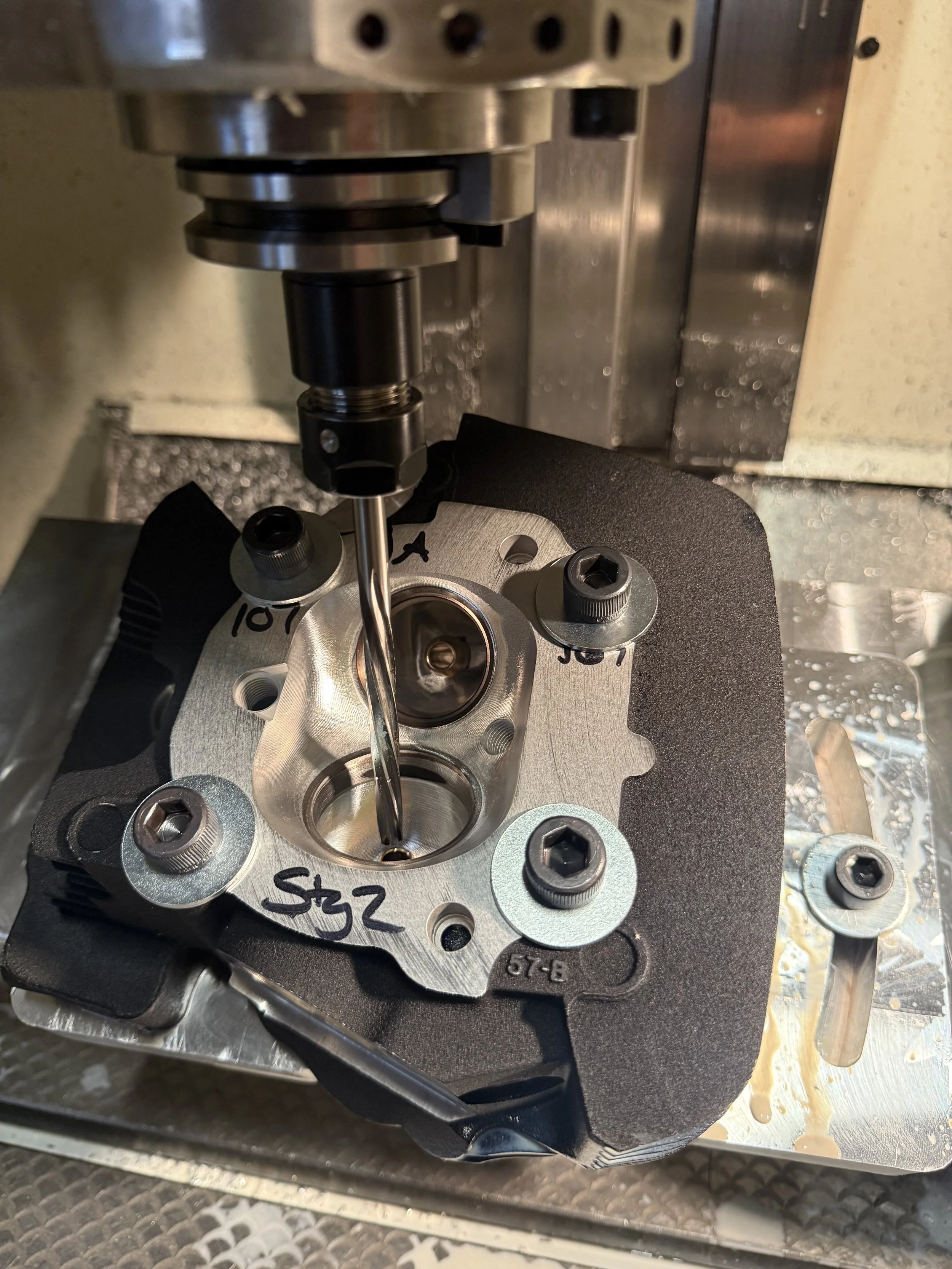

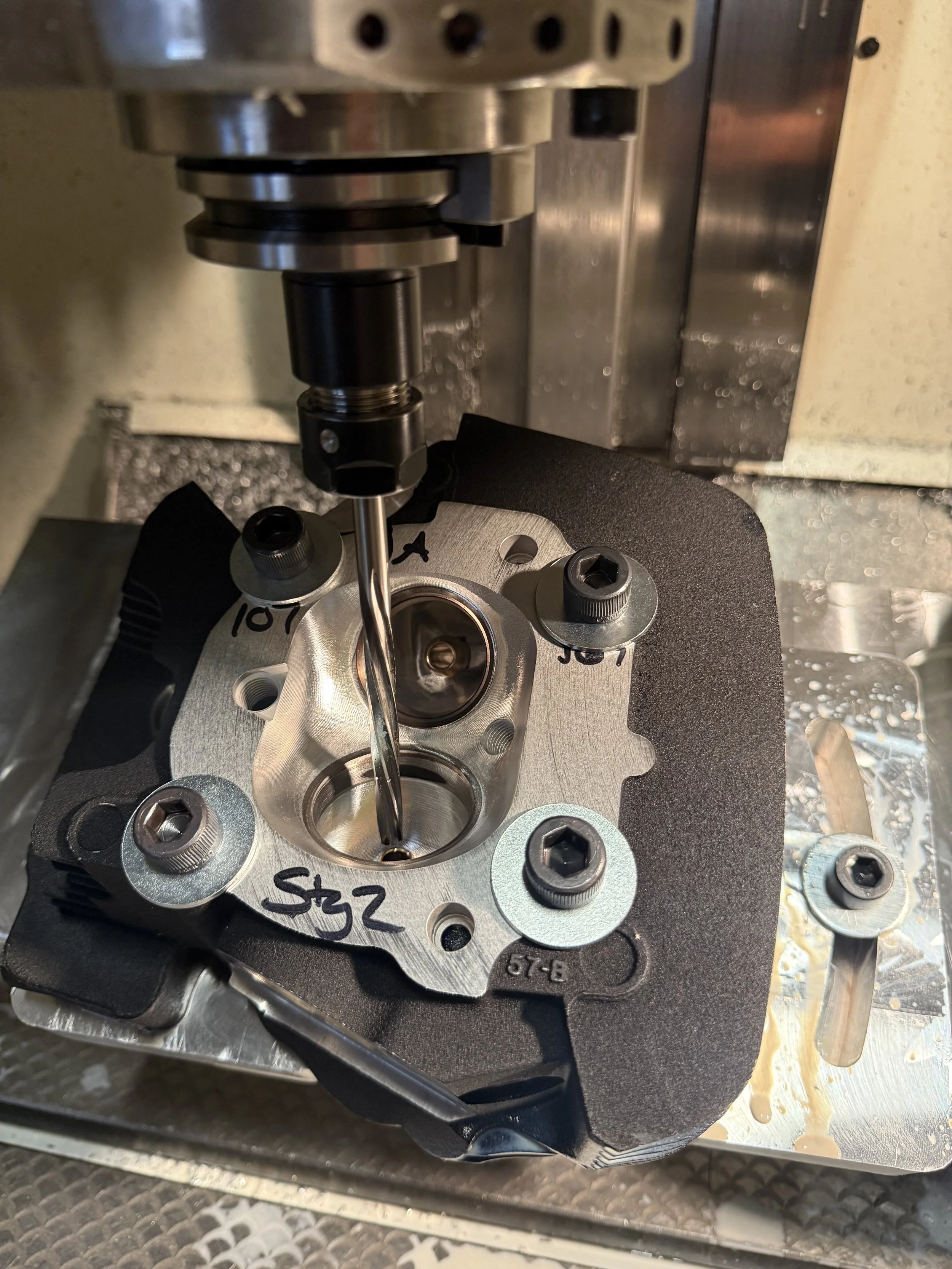

Full CNC porting of intake and exhaust runners, optimized for high-lift flow and velocity balance

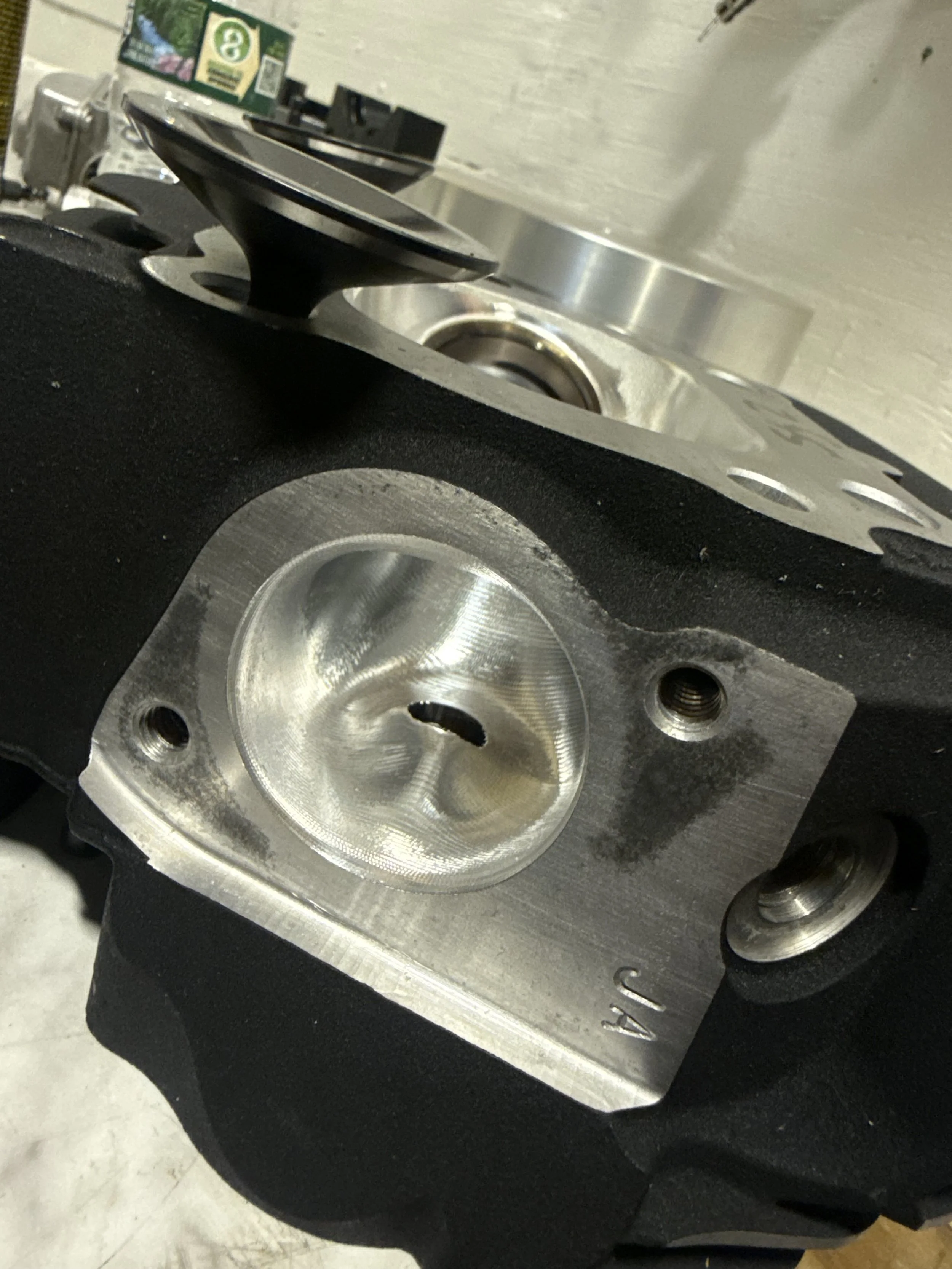

CNC-machined high-efficiency combustion chambers tailored for max compression and quench control

Precision 4-angle valve job on performance seats

2.100” intake valves / 1.650” exhaust valves

Corrected Seat Geometry As well as CSA / Throat Diameters

Upgraded bronze taper valve guides for superior heat transfer and long-term stability

Premium high-tension beehive valve springs matched for aggressive cam profiles

CNC deck for exact compression control and perfect gasket sealing

Final ultrasonic wash and professional assembly

Result: maximum airflow and combustion efficiency from CVO castings — engineered for race builds and high-compression performance engines.

Note: This is a send-in service for your existing cylinder-head cores.

Customer must ship in clean, rebuildable head cores for this service.

Pricing covers machining and labor only — no cores are supplied or exchanged.

Any additional parts or repairs required beyond the listed service will be quoted separately upon inspection.

.Race-level CNC development using stock castings, designed to extract every ounce of power while maintaining durability and reliability:

Complete disassembly and full inspection of all components

Deep cleaning and media blasting of chambers and ports

Full CNC porting of intake and exhaust runners, optimized for high-lift flow and velocity balance

CNC-machined high-efficiency combustion chambers tailored for max compression and quench control

Precision 4-angle valve job on performance seats

2.100” intake valves / 1.650” exhaust valves

Corrected Seat Geometry As well as CSA / Throat Diameters

Upgraded bronze taper valve guides for superior heat transfer and long-term stability

Premium high-tension beehive valve springs matched for aggressive cam profiles

CNC deck for exact compression control and perfect gasket sealing

Final ultrasonic wash and professional assembly

Result: maximum airflow and combustion efficiency from CVO castings — engineered for race builds and high-compression performance engines.

Note: This is a send-in service for your existing cylinder-head cores.

Customer must ship in clean, rebuildable head cores for this service.

Pricing covers machining and labor only — no cores are supplied or exchanged.

Any additional parts or repairs required beyond the listed service will be quoted separately upon inspection.